Servicing – preventive maintenance

Customer care does not end by handing over the workstation. We provide warranty and post warranty service for our customers. In case of a breakdown failure, we are able to provide servicing within a few hours of reporting the failure.

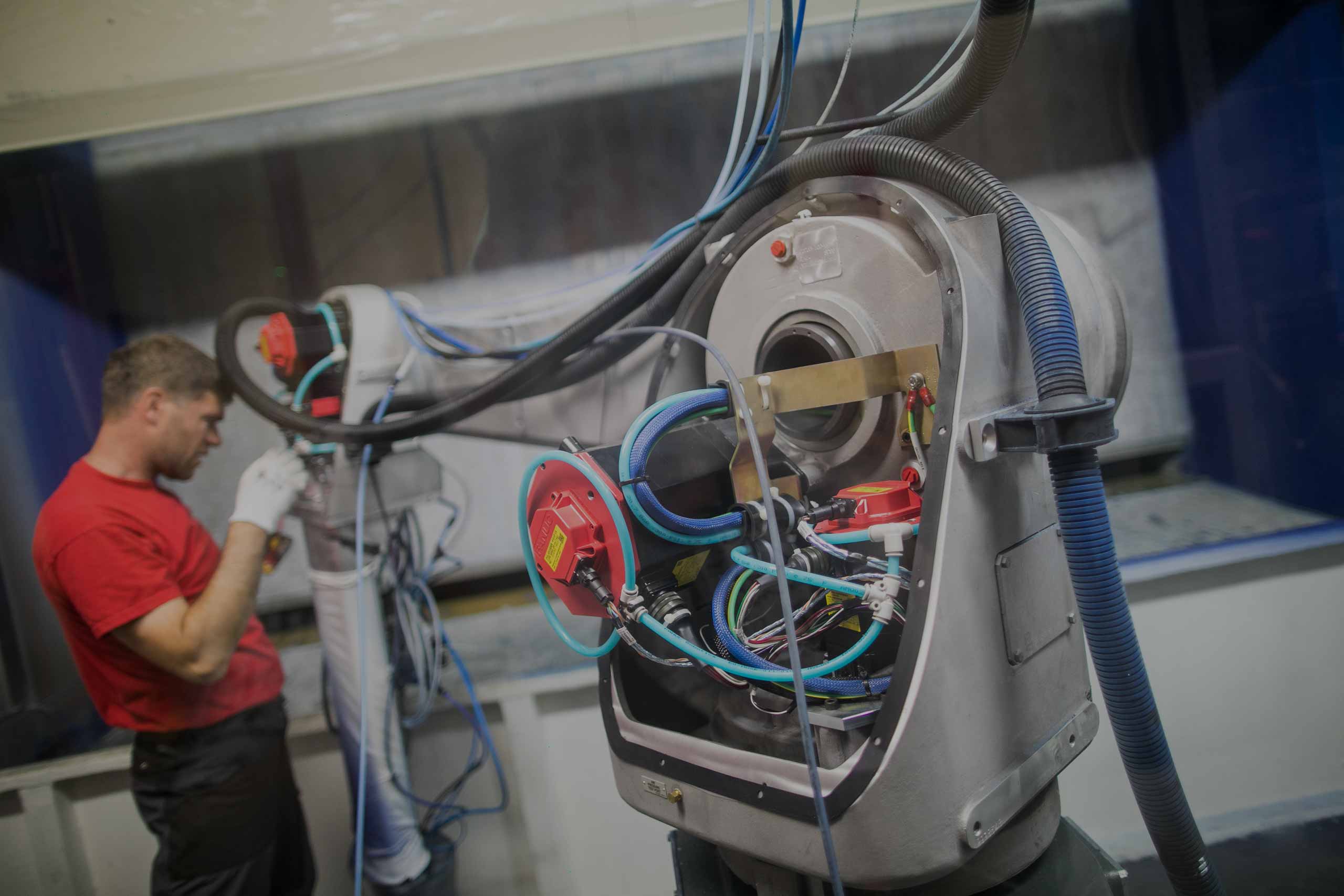

Preventive maintenance / General repairs

With regular maintenance you can extend service life of your devices. Part of preventive maintenance is to evaluate actual state of the system and repair any present electrical, mechanical or system failure.

As a FANUC Robotics system integrator we perform general repairs to mechanical and electrical parts of the Fanuc robot.

ROBOTIC PROGRAMMING

Robotic SK s.r.o. will help to improve your production processes so Fanuc robots can work faster and more efficiently. Our programmers have broad experience with practical applications such as welding, adhesives application, material handling, varnishing, palletizing and many more. Thanks to this we can help you program your robots, PLC systems as fast as possible and improve the production system, parameters and trajectories. Choose the most suitable robot and welding according to your application. We install safety features, cleaning stations, and we provide exhaustion according to the application.

PLC PROGRAMMING

Design, solutions and design of Siemens automation systems. Creation and modification of programs, hardware modifications of automation lines. Design and programming of visualizations using WinCC Flexible 2008 software. Custom-made electrical and pneumatic switchgear according to the requirements. Making of documentation in electronic form.

TRAINING

The way to increasing production, the quality of the production process leads through highly qualified personnel. Only trained workers can extend service life of your equipment, speed up production process, prevent frequent production failure, eliminate mistakes in breakdown failure.

Our company offers a wide range of end-user training courses. Besides basic courses we set the training program according to the customer’s requirements:

- Application training by type of the robot used

- Training for operators and programmers

- Maintenance training

The training center is equipped with the highest quality devices and technologies in its class: Fanuc, Fronius, Siemens, Festo, Schunk and others.

If you have any further questions about training, please contact our qualified staff.